Solid Carbide Tsvimbo

![]() Nhanganyaya yeSolid Carbide Rods

Nhanganyaya yeSolid Carbide Rods

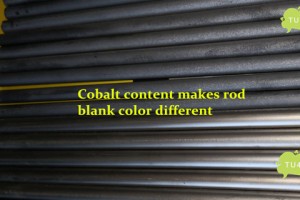

Solid carbide tsvimbo inonyanya kugadzirwa ne tungsten carbide, bhainda simbi cobalt uye zvimwe zvinoshanda zvinowedzerwa se fomura inoda, kuburikidza nezvinhu musanganiswa, extruding, pre-sinter, chimiro chinoshandurwa kugadzira maitiro uye sintered mune yakaderera kumanikidza. Iine mavara ekuomarara kwakanyanya, yakasimba simba, makemikari akatsiga, yakaderera yekuwedzera coefficient, magetsi uye kupisa kuitisa, iyo sintered tungsten carbide tsvimbo dzinoshandiswa zvakanyanya muindasitiri yekugadzira nharaunda, semuenzaniso, kugadzira micro kudhiraina muPCB indasitiri, electrode bar mune optical munharaunda indasitiri, chibooreso, chibooreso stock, tip, pusher, kupfeka nemishonga chaiyo zvikamu, CNC reamer uye mashizha ane inotonhorera gomba mune machine indasitiri.

Se carbide depot, Toonney tungsten simbi fekitori inogadzira yakakura tungsten alloy inosanganisira yakasimba tsvimbo, tsvimbo dzakatwasuka / dzakatwasuka inotonhorera buri, tsvimbo dzakaumbwa maererano nezvinodiwa nevatengi uye T yakaumbwa etc.

Solid tungsten carbide tsvimbo, hapana inotonhorera ducts mukati. Tine gumi mamakisi fomula zvinhu zvekushandisa zvakanyanya, semuenzaniso, tsvimbo dzePCB micro chibooreso, micro milling cutter, carbide saw blade, drills kune machining aruminiyamu chiwanikwa, mhangura base alloy, simbi base alloy uye; wolfram carbide etc. Isu tinonyatso kudzora mhando mune nhanho imwe neimwe inodiwa, tinogona kutaura kuti mhando yakanaka ndeimwe yezvakanaka zvinoita kuti timire mune ino indasitiri.

Wolfram carbide: Wolfram carbide inoumbwa neiyo wolfram uye carbide. Iyo nhema nhema hexagonal crystal ine metallic kubwinya, iyo kuomarara kwakafanana nedhaimani.Wolfram carbide yakanaka conductor yemagetsi uye kupisa, haigone kunyungudika mumvura, hydrochloric acid kana sulfuric acid, asi nyore kuparara mune yakasanganiswa mhinduro ye nitric acid uye hydrofluoric acid. Yakachena wolfram carbide haina kusimba, asi kuwedzera titanium kana cobalt uye sintered, iyo hukasha ichave yakakwira zvakanyanya. Wolfram carbide inonziwo tungsten carbide.

Tungsten simbi / Tungsten simbi:Tungsten inonziwo wolfram, iyo yakanyanya fomu yesimbi tungsten mune yekushandisa maindasitiri ndeye tungsten carbide. Toonney tungsten simbi fekitori yakaburitsa yakasimba carbide tsvimbo kwemakore mazhinji uye inowana mukurumbira wakanaka kumba nekune dzimwe nyika.

Kavha Details: Bhegi repurasitiki, rakazochengetedzwa mufuro raive, pakupedzisira kune katoni yekunze.

Mimwe Nyaya:Solid carbide tsvimbo dzinogona kuwanikwa kubva kune yedu yakajairwa kuverenga, inogona kupihwa semasampuli emahara. Kune yakasimba carbide tsvimbo ine isina kujairika mutengi yakakosha inodikanwa, ichabhadharwa. Ehe, vatengi vanofanirwa kubhadhara mari yekutumira. Kazhinji, iyo inotungamira nguva yemasampuli ichave iri mukati memazuva manomwe ekushanda.

Minimum Order Yakawanda: Iko hakuna kushomeka kwehuwandu hwehuwandu hweakasimba carbide tsvimbo yekutanga kutongwa odhiyo. Asi pachirongwa chechipiri, huwandu hwakazara hweakasimba carbide matanda haafanire kunge ari pasi pe1000 USD.

Nguva yekuendesa: 7-15 mazuva ekushanda

![]() Kucheka Zvishandiso Giredhi Tafura uye Kushanda

Kucheka Zvishandiso Giredhi Tafura uye Kushanda

| Giredhi | Co% | Zviyo Siz (μm) | Kuwandisa (g / cm3) | Kuoma (HRA) | TRS (N / mm2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TF06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08S | 8.0 | 0.3 | 14.5 | 93.6 | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 | 4800 |

![]() Yakakurudzirwa Kunyorera

Yakakurudzirwa Kunyorera

| Giredhi | Yakakurudzirwa kunyorera |

| TU90 | Yekucheka maturusi ekugadzirisa michina yakakwenenzverwa (HRC65-70), hardwood uye yakakwirira polishing cutters. Yakanakira vatemi vanopedza machining 316L isina simbi |

| TF06 | Yekucheka maturusi ekugadzirisa aruminiyamu magnesium alloy, graphite uye inoumbwa fiber. |

| TU06 | YePCBB micro-chibooreso uye magumo machina machira epamusoro akakwira simbi simbi. |

| TU08 | For pcb micro-chibooreso, Mini azvikuya aricheke. |

| TU08S | Kune micro pcb chibooreso, maturusi ekucheka eefis machining akadzima zvinhu (HRC60-65), 316L simbi isina simbi, yakakwirira polishing simbi jira uye nesilicon simbi jira remota. |

| TU40 | For zvakajairika chibooreso ikakuruma, magumo chigayo uye punching vanofa. |

| TU40F | Kune yakajairwa chibooreso zvishoma, kumagumo chigayo machina titanium chiwanikwa, isina simbi uye grey kukanda simbi. |

| TU40S | Yekucheka maturusi emuchina 316L simbi isina chinhu, yakanakisa zvinhu kune akajairika macircuit cuctters. |

| TU44 | Yekucheka maturusi ekushandisa machina titanium chiwanikwa, kupisa isingadziviriri chiwanikwa, simbi isina simbi, yakadzimwa simbi (HRC55 uye pamusoro), pfumbu yakakanda simbi. |

| TU25 | Yekucheka maturusi machining kupisa kurapwa simbi (Kuomarara HRC45 uye pamusoro), simbi yakakanda, simbi isina simbi. |

| TU45 | Yekucheka maturusi ekugadzirisa titanium, kupisa kupisa chiwanikwa, simbi isina simbi, simbi yakadzimwa (HRC60 uye pamusoro) |

| TU55 | Giredhi ine yakakwira tsvuku-kuomarara, yakanaka yekucheka maturusi machining yakanyanya tembiricha inodzivirira chiwanikwa, yakadzima simbi (HRC60 uye pamusoro) uye titanium chiwanikwa |

![]() Tsananguro yeSolid Carbide Tsvimbo

Tsananguro yeSolid Carbide Tsvimbo

| Dia. Ø mm |

Kushivirira. (Mm) | Kureba (mm) | Tol. (Mm) | Dia.Ø mm mm | Kushivirira. (Mm) | Kureba (mm) | Tol. (Mm) |

| 2.0 | + 0.30 / + 0.15 | 330 | 1.5 | 16.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 2.5 | + 0.30 / + 0.15 | 330 | 1.5 | 17.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.0 | + 0.50 / + 0.30 | 330 | 1.5 | 17.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.5 | + 0.50 / + 0.30 | 330 | 1.5 | 18.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.0 | + 0.50 / + 0.30 | 330 | 1.5 | 18.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.5 | + 0.50 / + 0.30 | 330 | 1.5 | 19.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.0 | + 0.50 / + 0.30 | 330 | 1.5 | 19.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.5 | + 0.50 / + 0.30 | 330 | 1.5 | 20.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.0 | + 0.50 / + 0.30 | 330 | 1.5 | 20.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.5 | + 0.50 / + 0.30 | 330 | 1.5 | 21.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.0 | + 0.50 / + 0.30 | 330 | 1.5 | 21.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.5 | + 0.50 / + 0.30 | 330 | 1.5 | 22.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.0 | + 0.50 / + 0.30 | 330 | 1.5 | 22.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.5 | + 0.50 / + 0.30 | 330 | 1.5 | 23.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.0 | + 0.60 / + 0.30 | 330 | 1.5 | 23.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.5 | + 0.60 / + 0.30 | 330 | 1.5 | 24.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.0 | + 0.60 / + 0.30 | 330 | 1.5 | 24.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.5 | + 0.60 / + 0.30 | 330 | 1.5 | 25.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.0 | + 0.60 / + 0.30 | 330 | 1.5 | 25.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.5 | + 0.60 / + 0.30 | 330 | 1.5 | 26.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.0 | + 0.60 / + 0.30 | 330 | 1.5 | 26.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.5 | + 0.60 / + 0.30 | 330 | 1.5 | 27.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.0 | + 0.60 / + 0.30 | 330 | 1.5 | 27.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.5 | + 0.60 / + 0.30 | 330 | 1.5 | 28.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.0 | + 0.70 / + 0.30 | 330 | 1.5 | 28.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.5 | + 0.70 / + 0.30 | 330 | 1.5 | 29.0 | + 0.8 / + 0.3 | 330 | 1.5 |